Metal Stampings, Fabrication, & Machining.

Industries We Serve Include Aerospace & Defense, Industrial, Medical, Recreation & Power Sports, Transportation. Our Certifications Include IATF 16949, AS9100, ITAR, ISO 9001, ISO 14001

What We Do

A one-stop shop for all metal forming and machining needs, OGS exceeds customer expectations with U.S.A-made metal stampings, fabrications, and Swiss and CNC machined parts for several industries.

Stampings

With two stamping facilities & an in-house tool & die shop, we focus on light to mid-level stampings (20 to 500-ton press capacity and 0.002″ – 0.375″ thickness). Some of our product offerings include shims, electrical contacts, clips, and clamps.

Stampings

With two stamping facilities & an in-house tool & die shop, we focus on light to mid-level stampings (20 to 500-ton press capacity and 0.002″ – 0.375″ thickness). Some of our product offerings include shims, electrical contacts, clips, and clamps.

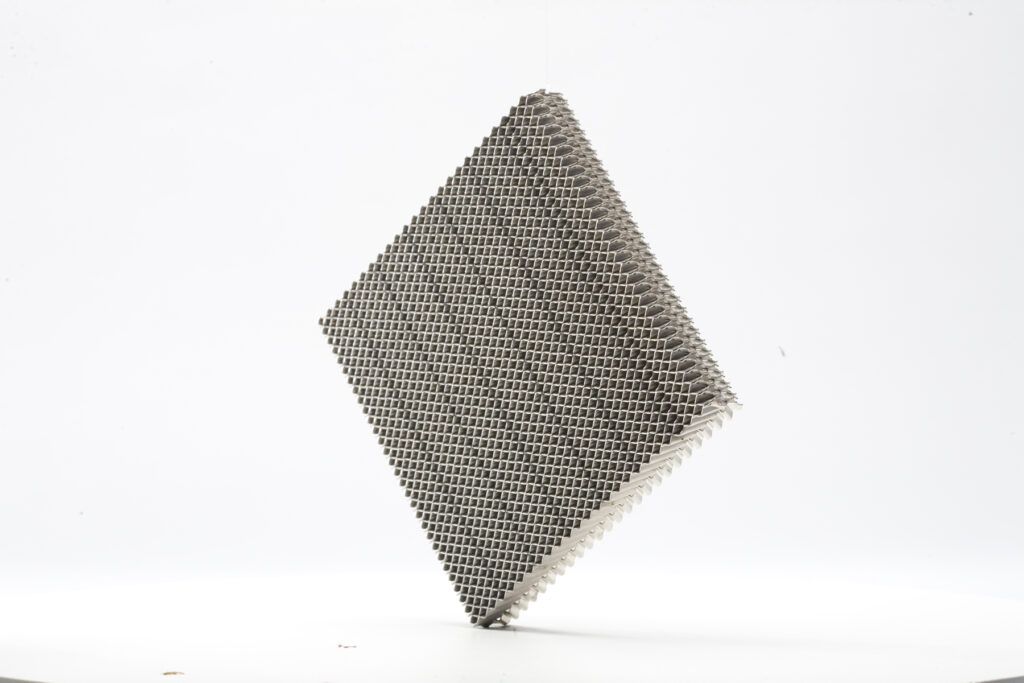

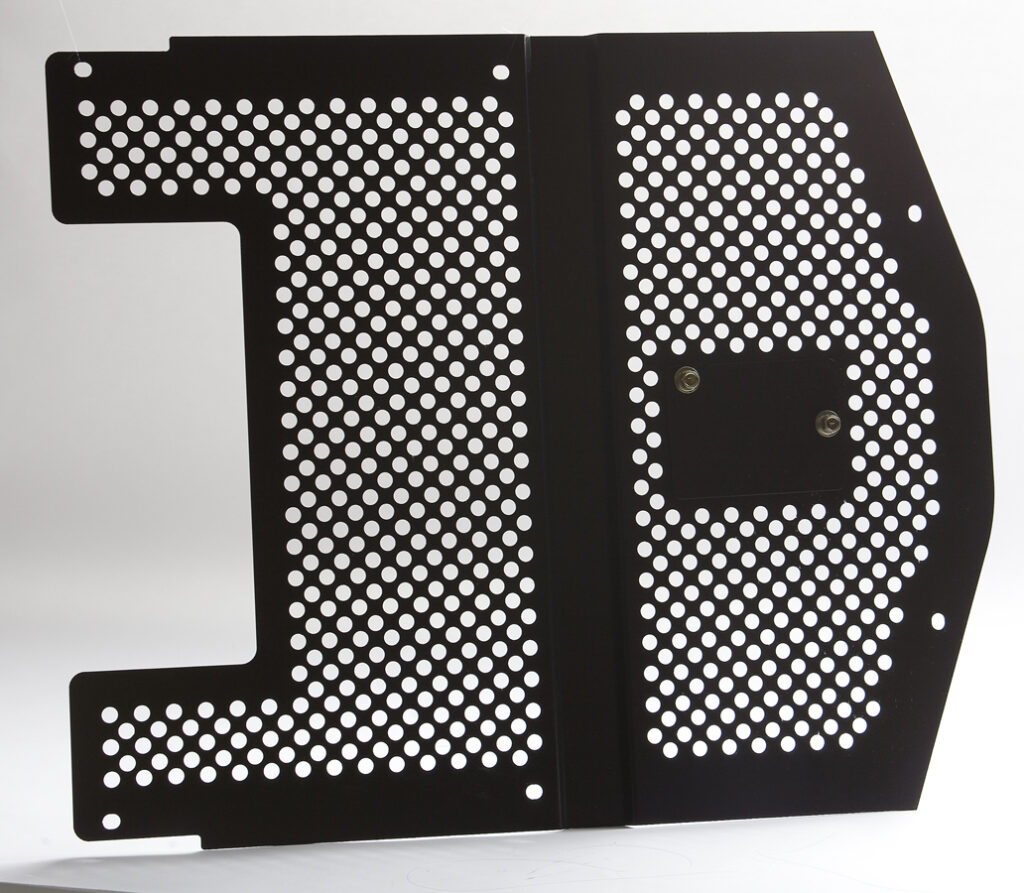

Fabrication

Our full metal fabrication shop features a state-of-the-art fiber laser, multiple press brakes, a CNC punching machine, and three robotic welders. A sampling of our fabricated products includes gaskets, enclosures and chassis, metal panels, brackets, and heat sinks for electronic devices.

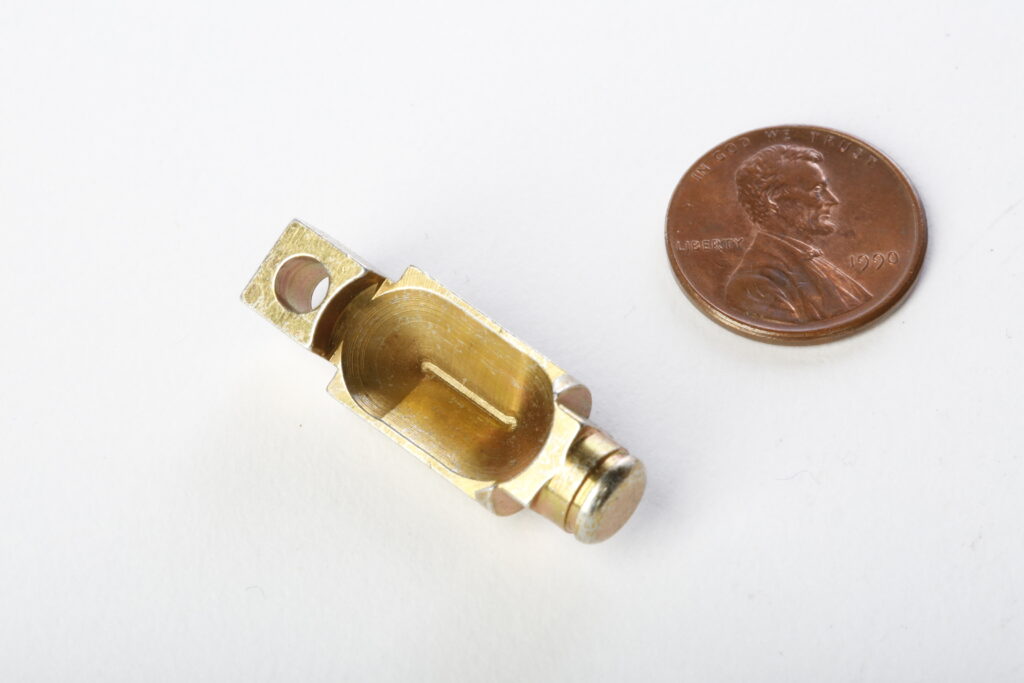

Machining: CNC & Swiss

From high-precision aerospace screw machined components to exotic materials for the oil & gas industry, we offer full-scale CNC machining services. Some of our machined products include fasteners, bushings, connectors, and couplings.

Machining: CNC & Swiss

From high-precision aerospace screw machined components to exotic materials for the oil & gas industry, we offer full-scale CNC machining services. Some of our machined products include fasteners, bushings, connectors, and couplings.

LEM Tools

For 60+ years, OGS Industries has been the trusted manufacturer of blind rivet nut installation tools used in every industry from aerospace and defense to industrial and power sports.

Industries Served

For more than 60 years, OGS has been helping businesses improve their application performance, reliability, and longevity while meeting their most demanding compliance requirements and standards by being AS9100, ISO 9001, IATF 16949, and ISO 14001 certified.

About OGS

At OGS Industries, we’ve been in the metal stamping and fabrication business since 1959. We’re an established, U.S.-based manufacturer with capabilities that cover the entire production process, including stamping, fabrication, machining, in-house tool and die, inventory stocking programs, and even delivery. With us, you have a one-stop metal manufacturing partner for better efficiency and an optimized supply chain.

About OGS

At OGS Industries, we’ve been in the metal stamping and fabrication business since 1959. We’re an established, U.S.-based manufacturer with capabilities that cover the entire production process, including stamping, fabrication, machining, in-house tool and die, inventory stocking programs, and even delivery. With us, you have a one-stop metal manufacturing partner for better efficiency and an optimized supply chain.

Interested in Working for OGS?

We’re a 3rd-generation family-owned company with a deep appreciation for each of our employees. We can’t do what we do without you. Along with paid vacation, overtime availability, and flexible work schedules, our employees love us for our laid back management style and a welcoming work culture.

Trade Shows We Are Attending

As a complete source for your full-service needs, we can help you consolidate your vendor base to save time and money. We’ve been family-owned and operated since our inception, and we aim to offer outstanding expertise, next-level customer service, and a passion for excellence that is unmatched in the industry. Our team takes pride in staying on top of the latest equipment, technologies, and manufacturing innovations. Feel free to join us at our next trade show to see what we have in store.

Get the Latest Insights from OGS

Check out our blogs to learn more about our processes at OGS, catch up on the latest news, and get a feel for what goes on in a metal shop.