Shims and light pressings are small but essential metal components that play critical roles in a diverse array of applications. Used to ensure precise alignments, proper spacing, and accurate assembly of larger parts, shims and light pressings help enhance part reliability and improve operational efficiency. Shims and light pressings are commonly used in industries that have extremely rigid tolerance requirements, such as the aerospace and defense, medical, and transportation industries. For this reason, it’s essential to partner with a trusted shims and light pressings supplier that has the expertise and capabilities to meet strict standards.

Understanding the Impact of Quality Shims and Light Pressings

A high level of quality is non-negotiable when it comes to shims and light pressings. Both are indispensable to a variety of industries, but especially those that require meticulous attention to detail and precision.

In the aerospace industry, for instance, shims and light pressings are crucial for maintaining structural integrity, minimizing vibration, and achieving precise alignments in the assembly of an aircraft. Similarly, industrial applications rely on shims and light pressings for the accurate positioning of machinery. This results in increased operational efficiency and decreased wear and tear on equipment, both of which contribute to cost savings over the long run.

Beyond that, high-quality shims and light pressings are vital to the overall integrity of end-use products and, consequently, to a manufacturer’s reputation.

Key Considerations When Selecting a Shims and Light Pressings Supplier

When searching for a shims and light pressings supplier who can fully support your metal manufacturing needs, be sure to consider their expertise, capabilities, and reputation within the industry. Look for certifications and transparent quality control processes that showcase their commitment to excellence.

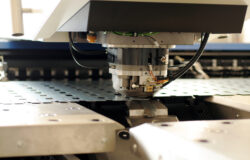

Equally important is the supplier’s capabilities, as the production of shims and light pressings presents unique challenges for metal manufacturers. The precision of these small components often comes down to the micrometer and they may possess unique geometries or complex designs. The right shims and light pressings supplier will have advanced manufacturing processes, specialized equipment, and highly skilled technicians in place to meet these challenges.

On top of that, accurate material selection is absolutely critical. A variety of factors need to be taken into account, including corrosion resistance, strength, and durability. The right shims and light pressings supplier will be able to provide expertise on which material will be best suited for your particular application.

Overcoming Cost Concerns: Balancing Quality and Budget

The cost of shims and light pressings is often reflective of the complexities involved in manufacturing them. For many, this might seem prohibitive at first glance.

However, the value provided by shims and light pressings from a qualified supplier can drastically balance this out through:

- Enhanced Precision and Performance – Investing in high-quality shims and light pressings ensures that your machinery, equipment, or structures operate with the utmost precision and performance thanks to better alignments, accurate spacing, and optimal assembly.

- Improved Durability and Longevity – Trusted shims and light pressings suppliers use only high-quality materials and implement the most advanced manufacturing techniques to ensure part durability and long-term performance. This reduces the need for replacements and saves money on new parts and labor.

- Mitigated Risk and Improve Reliability – By investing in high-quality shims and light pressings, you can minimize the risk of part failure or performance degradation.

- Cost Savings Over the Long Haul – High-quality shims and light pressings can save on expenses related to repairs, labor, and maintenance by providing superior levels of performance and reliability. Additionally, a skilled shims and light pressings supplier can offer expert advice to optimize your application and identify other potential opportunities for reducing costs.

- Ensured Industry Compliance and Reputation – Reputable shims and light pressings suppliers can help ensure that your products meet industry compliance standards and regulations. By delivering products that consistently meet or exceed customer expectations, you can strengthen your position in the marketplace and maintain an edge over your competitors.

Experience the Advantage of Expertly Manufactured Metal Parts with OGS Industries

At OGS Industries, we have 60+ years of experience in manufacturing precision metal components for a variety of critical applications. Our sheet metal fabrication, metal stamping, and machining services are backed by our diligent commitment to exceptional quality and the highest level of customer service. We utilize the latest technology and most advanced manufacturing methods to ensure that every component we produce meets your exacting standards.

Connect with our team today to learn more about how our capabilities enable us to provide you with the gold standard in shims, light pressings, and more.