As concerns over project lifecycles, supply chain disruptions, and business reputation continue to take center stage, more effective supplier risk management is becoming a top priority for many businesses. In fact, so far in 2023, 70% of organizations have reported increasing their investments in supplier risk detection.

When forming a new partnership with a metal manufacturer, effective supplier risk management can help ensure project timelines, maintain quality standards, and control costs production costs.

Understanding Supplier Risks in Metal Manufacturing

Metal manufacturers face a variety of risks that can impact their customers. These risks may include raw material availability, quality control issues, supply chain disruptions, and regulatory compliance.

Any one of these risks can have a significant impact on project schedules, product quality, and overall costs. This, in turn, can lead to delayed deliveries, cost overruns, and potential reputational damage. Working with a metal manufacturer that understands these risks and takes steps to mitigate them is essential to protecting the operational continuity of your own company. But beyond that, there are steps you can take to shore up your supplier risk management for metal suppliers.

Key Steps in Effective Supplier Risk Management

Step 1: Supplier Risk Assessment and Selection

First, when you’re in the early stages of looking for a metal manufacturing partner, it’s a good idea to establish supplier evaluation criteria.

Looking at aspects of the company such as experience, certifications, financial stability, and capacity can help you gain a better understanding of their capabilities and whether they are the right fit for your needs. Doing so is essential to ensuring project success.

Additionally, you may want to conduct thorough due diligence and background checks on potential suppliers. Look for any red flags that may indicate that the partner is not reliable or is headed for some financial trouble.

Step 2: Contractual Agreements and Risk Mitigation

Next, when you enter into a partnership with a new metal supplier, it’s important to negotiate and draft comprehensive contracts with clear terms and agreements. Establishing detailed specifications, delivery schedules, and quality standards can help ensure that mechanisms are in place to promote clarity and collaboration. You can also implement risk mitigation measures such as quality control requirements, penalty clauses, and IP protection agreements.

Step 3: Ongoing Supplier Monitoring and Performance Evaluation

Regularly re-evaluating your metal manufacturing partner is a core component of supplier risk management. Robust supplier performance monitoring systems can help you can identify issues early on and address them quickly. With open lines of communication between you and your supplier, you can also create a relationship that facilitates close collaboration and minimizes the risk of disruption.

Step 4: Supplier Collaboration and Relationship Management

And finally, it’s a good practice to nurture strong relationships with your suppliers. By keeping lines of communication open and engaging in joining risk mitigation, you can help promote mutual trust, better communication, and a shared commitment to project success. Beyond this, a strong two-way relationship with your metal manufacturer can help you develop a collaborative strategy for identifying issues and adopting continuous improvement initiatives for a more proactive (and preventative) approach.

Tools and Techniques for Supplier Risk Management

While supplier risk management is a somewhat nebulous concept, there are some tools and techniques you can use for a stronger and more effective strategy, including:

- Software solutions – There are various software solutions that are designed for managing supplier relationships. With these programs, you can streamline communication, track performance over time, and monitor for potential risks as they arise.

- Supply chain visibility tools – If you want to monitor supplier performance more closely, supply visibility tools are an ideal solution. These tools allow you to track inventory and identify potential bottlenecks or disruptions in real-time.

- Data analytics – Data analytics are universally useful in every facet of business, but particularly in supplier risk management. Data analytics tools can empower you to identify trends, patterns, and potential risks in supplier performance and supply chain operations. With this, you can stay ahead of risks with proactive management strategies.

Gain a Trusted Metal Parts Supplier with OGS Industries

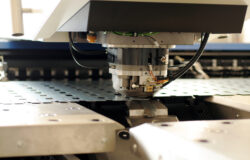

OGS Industries has been a trusted supplier of precision metal components for 60+ years. With our dedication to the highest level of part quality and superior customer service, we have been the go-to provider of metal stampings, sheet metal fabrication, and metal machining services for companies such as Volvo, GE, and Boeing.

We believe that collaboration and knowledge sharing makes us stronger. That’s why we work closely with each of our customers to ensure that every part we produce meets their expectations.

Are you looking for a metal manufacturing partner you can trust? Get in touch with our team of experts today to get started.