Metal brackets are one of the most important components in the modern day. Whether you’re in aerospace, transportation, medical, or the industrial sector, chances are that some part of your operations relies on metal brackets for structural integrity.

But finding high-strength, custom metal brackets that meet rigorous standards and perform in critical environments can be tricky. Fortunately, there are manufacturers out there, like OGS, who specialize in producing metal brackets for industries with zero room for failure. For that, metal stamping, metal fabrication, and CNC machining are critical.

Ensuring Durability in Custom Metal Brackets with Precision Metal Stamping

For industries that rely on custom metal brackets, durability is key to maintaining the safety and functionality of critical equipment. Components like heavy duty industrial shelf brackets need to withstand extreme conditions and heavy loads while maintaining their structural integrity over time.

To accomplish this, manufacturers often turn to precision metal stamping. This is a method that ensures that each custom metal bracket is designed and manufactured to meet exact specifications, using advanced techniques to guarantee strength and durability.

By carefully controlling each stage of the stamping process — including material selection, process parameters, and final quality checks — manufacturers can produce metal brackets that maintain their integrity even in demanding environments.

For example, custom brackets used in aerospace or defense applications must be engineered to handle stress, vibrations, and temperature extremes without failing. Precision metal stamping allows manufacturers to create parts that not only meet these rigorous demands but also provide long-term reliability.

Custom Metal Fabrication for Brackets with Unique and Complex Requirements

When off-the-shelf metal brackets aren’t sufficient to meet the unique demands of your project, custom metal fabrication offers the flexibility and precision required to create tailored solutions. Industries such as aerospace, medical, and defense often benefit from this, as they require highly specialized brackets that can meet complex specifications while providing reliable performance in challenging environments.

Custom metal fabrication allows for the creation of these brackets. With the ability to design metal brackets to meet the specific requirements of unique applications (whether they need to support intricate equipment assemblies or handle extreme temperature variations) manufacturers can develop parts that meet performance and longevity requirements.

This is particularly helpful when operation systems require brackets with non-standard shapes, angles, or materials. Whether you’re working on a project that demands tight tolerances, high-strength materials, or innovative designs, you’ll want to partner with a manufacturer who can deliver custom metal brackets that meet strict standards and your project’s performance goals.

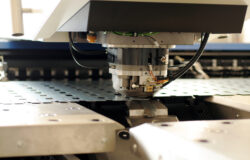

CNC Machining for Precision and Flexibility for Custom Metal Brackets

When it comes to custom metal brackets, achieving both precision and flexibility in design is critical for ensuring that the specific needs of your application are met. CNC machining can offer unparalleled accuracy and adaptability, making it ideal for producing complex brackets that need to fit into exacting systems while maintaining strength and durability.

CNC machining allows for high-precision manufacturing, where even the most intricate details can be executed with consistent accuracy. This level of precision is crucial when working on projects in industries like aerospace, defense, and medical, where components must meet tight tolerances and specific geometries. CNC machining ensures that each custom bracket is produced with exceptional attention to detail, providing a perfect fit for its intended application.

Flexibility is another key advantage of CNC machining. Whether you need prototypes or large production runs, CNC machining can accommodate a wide range of project requirements. It allows for the use of a variety of materials, including aluminum, stainless steel, and exotic alloys, ensuring that your custom brackets can be manufactured to perform under even the most demanding conditions.

Solve Your Metal Bracket Challenges with OGS Industries

At OGS Industries, we know that durability and precision are paramount when it comes to custom metal brackets for critical infrastructure and equipment. With our expertise in precision metal stamping, custom metal fabrication, and CNC machining, we deliver high-quality, tailored components that meet the most stringent performance standards for a range of industries.

By partnering with OGS, you gain access to advanced manufacturing solutions designed to address your unique challenges — whether you need precision, strength, or flexibility. Let us help you ensure the reliability and longevity of your critical components.

Contact us today to discuss how our industry-leading capabilities can provide the custom metal brackets your project demands, backed by our commitment to excellence.