For industries like aerospace, automotive, and defense, every metal component needs to perform at the highest level. This often means that metal parts need to meet tight tolerances and rigorous quality standards in order to ensure safety and reliability. This, in turn, calls for precision in custom metal stamping.

At OGS Industries, we’ve built our reputation on delivering advanced metal stamping solutions that not only meet but exceed the demands of these high-stakes industries. Let’s take a closer look at our metal stamping capabilities, and how our expertise, precision, and commitment to quality make us the ideal partner for high-performance applications across a variety of sectors.

Looking for unmatched precision in custom metal stamping? — Get in touch with our team today for a free quote.

Unmatched Precision and Consistency in Custom Metal Stamping

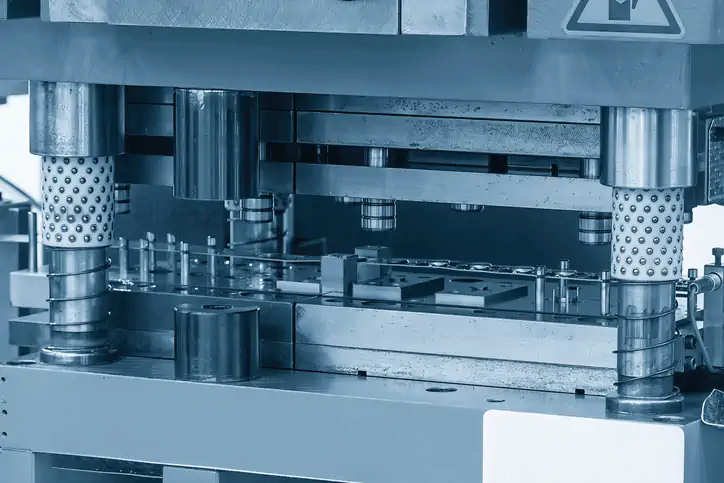

At OGS Industries, precision and consistency are at the core of everything we do. Our state-of-the-art custom metal stamping technology ensures that every part meets the high standards of industries like aerospace, defense, transportation, and medical. With over 40 stamping presses, we can handle a wide range of production needs, from simple components to highly intricate, complex parts.

Our focus on tight tolerances means that we deliver uncompromising accuracy to even the most demanding applications. Whether it’s high-stakes engine components for transportation or mission-critical parts for defense systems, our advanced machinery and proven processes are designed to meet the tightest specifications.

We’re also equipped to handle high-volume production runs as well as smaller, more specialized orders. With an in-house tool & die shop for building and repairing custom tools, and the ability to manage runs from 500 to 50,000 parts, we offer unmatched flexibility.

Custom Metal Stamping Solutions for Complex Needs

Our customers range from Fortune 5000 companies like Volvo and Lockheed Martin to smaller local and regional businesses. That’s why we offer custom metal stamping solutions tailored to meet the unique requirements of each client. If you need something tailored and specific, our team of engineers will find the solutions that align with your exact needs.

We take a collaborative approach to every project, working closely with your team from start to finish. Our engineering support is designed to optimize the process and ensure the best outcomes for your product.

With our operations spread across two stamping facilities and supported by an in-house tool & die shop, we provide the flexibility needed to solve even the most challenging manufacturing tasks. Whether it’s producing delicate components or handling large-scale orders, OGS delivers custom metal stamping solutions that meet your complex needs.

Diverse Material Options for Every Application

We work with a wide variety of materials at OGS to meet the specific needs of high-performance applications across multiple critical industries. Our extensive options for custom metal stamping include steel, aluminum, copper, brass, and specialty alloys, ensuring that we can accommodate diverse project requirements and performance standards.

Our deep expertise in material science also means we understand the unique properties of each material—such as strength-to-weight ratios, corrosion resistance, and overall durability. This knowledge allows us to guide clients in selecting the best material for their specific application, whether it’s a lightweight aluminum component for the aerospace industry or a corrosion-resistant part for harsh environments in the marine and defense sectors.

Industry Expertise Across High-Performance Sectors

Along with our extensive custom metal stamping capabilities and metal fabrication services, we bring decades of experience providing solutions to high-performance sectors like aerospace, automotive, defense, industrial, and more. This expertise allows us to produce metal-stamped parts that meet the exacting standards of these industries for maximum reliability and precision in every application. We’ve made parts for critical applications like airframes, engine components, medical implants, and safety-critical automotive parts. Whether parts must operate under high temperatures, extreme pressures, or in corrosive environments, we ensure every part we produce will meet your highest standards.

Commitment to Quality and Compliance in Custom Metal Stamping

And finally, our commitment to providing the highest level of custom metal stamping services is reflected in our steadfast dedication to quality and compliance. We maintain some of the strictest certifications in manufacturing, including AS9100, IATF 16949, ISO 9001, and ISO 14001. We’re also an ITAR-registered facility.

Our rigorous quality control processes are designed to ensure that every part we produce meets the strictest standards for safety, performance, and reliability. From initial inspection to final testing, our advanced quality and inspection equipment enables us to verify that each component performs as designed.

Trust OGS for Your Custom Metal Stamping Needs

At OGS Industries, our advanced metal stamping capabilities, commitment to precision, and focus on quality have made us a trusted partner for high-performance industries since 1959. Whether you need intricate components for aerospace applications or robust parts for the automotive sector, we offer custom solutions tailored to your specific application. Our experience across a range of materials and our industry expertise allow us to deliver parts that perform under the most demanding conditions.

With additional services such as in-house tool and die, fabrication, and machining, OGS is your one-stop manufacturing partner. Reach out to our team today to discuss how we can support your next project.