In the aerospace industry, even the smallest deviation in components can compromise overall system safety, efficiency, and performance. Metal parts must be able to withstand extreme conditions, including the intense pressures of high-altitude flights and extremely high operating temperatures. As a result, tolerances are a cornerstone of aerospace manufacturing. For this, manufacturers often turn to CNC machining.

With the combination of advanced technology and expert craftsmanship, CNC aircraft parts can be produced with exceptional levels of accuracy, consistency, and repeatability. For aerospace OEMs, this means access to parts that meet stringent specifications and perform reliably in mission-critical applications.

At OGS Industries, we specialize in CNC machining solutions designed to exceed the high standards of aerospace manufacturing. Whether it’s crafting complex geometries or maintaining micrometer-level tolerances, our expertise ensures that your projects are executed with unmatched precision.

The Aerospace OEM Challenge: Precision and Performance

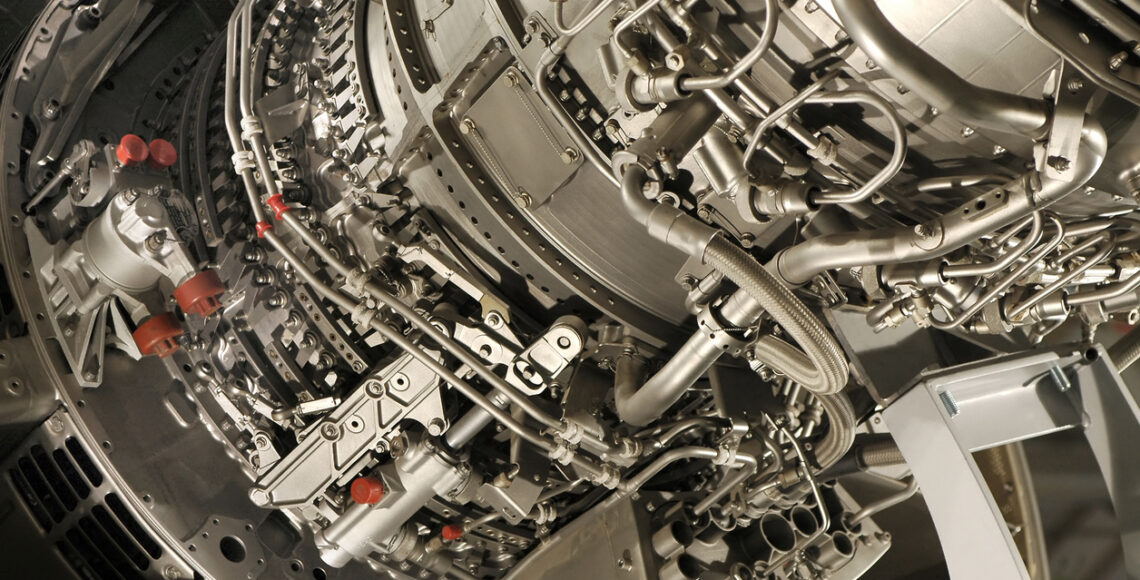

For aerospace OEMs, the need for precision goes beyond standard manufacturing — it defines the integrity of every flight-critical component. Engine parts, structural assemblies, and complex geometries all demand exceptionally tight tolerances. Achieving this level of precision ensures components fit seamlessly within larger systems, supporting optimal performance and safety.

OGS Industries understands these challenges. Our CNC machining capabilities are tailored to eliminate the risk of deviations, ensuring every part meets the highest standards of precision and consistency. Plus, by leveraging advanced technologies and rigorous quality control processes, we offer aerospace OEMs the reliability and performance they need to thrive in a demanding industry.

OGS’s Expertise in Precision CNC Aircraft Parts

Aerospace OEMs require CNC aircraft parts that meet exceptional standards of precision, durability, and reliability. At OGS, we deliver on these demands with an integrated approach to manufacturing that blends cutting-edge CNC machining, comprehensive fabrication services, and a commitment to quality assurance.

Advanced CNC Machining Capabilities

OGS’s multi-axis CNC machines are designed to handle the complexity of aerospace components with unmatched precision. Whether it’s intricate geometries or tight tolerances measured in microns, our machines ensure consistent accuracy across production runs. Our expertise extends to working with high-performance materials like titanium, aluminum alloys, and stainless steel.

Fabrication and Machining Capabilities

Our precision CNC machining services are further enhanced by in-house fabrication capabilities, allowing us to create seamless assemblies tailored to aerospace applications. From TIG and MIG welding to spot welding, our solutions deliver durable connections and ensure structural integrity across complex assemblies.

By combining machining, fabrication, and finishing under one roof, we can streamline production timelines, reduce costs, and minimize logistical complexity for our aerospace OEM partners.

Quality Assurance

Finally, all CNC aircraft parts that we manufacture are subject to rigorous quality control measures. We use cutting-edge inspection tools to ensure real-time accuracy during the machining process, verifying that every part meets exacting specifications. And with certifications like AS9100 and ISO 9001, and ITAR registered, we provide confidence that our processes adhere to the highest standards required by the aerospace industry

Tailored Solutions for Aerospace OEMs

At OGS, we understand that every aerospace OEM project comes with unique design and performance requirements. That’s why our approach is centered on customization, ensuring all CNC aircraft parts meet strict specifications as well as the critical demands of aerospace applications.

When it comes to customization, we work closely with OEMs to develop tailored solutions through design collaboration. Our internal engineering team partners with our aerospace clients to refine designs for manufacturability. Beyond that, we also offer extensive performance optimization, from material selection to optimizing the machining processes themselves.

We also have a track record of success working with leading aerospace engine builders and distributors. For engine builders, we’ve delivered high-precision components like turbine housings, brackets, and flow-critical parts that ensure engine reliability and efficiency. And for distributors, we offer scalable production capabilities for a consistent supply of high-quality CNC aircraft parts for distributors managing large inventories and stringent supply chain timelines.

Why Choose OGS for CNC Aerospace Parts?

When precision and reliability are non-negotiable, aerospace OEMs turn to OGS. With decades of experience in high-performance manufacturing, we’ve built a reputation for innovation, quality, and a customer-first approach that sets us apart in the aerospace industry.

From concept to delivery, OGS offers a seamless, full-service solution. Our in-house design support, fabrication capabilities, and rigorous quality assurance processes mean you get everything you need under one roof—saving time and ensuring consistency. In particular, our advanced CNC machining capabilities and expertise in aerospace-grade materials ensure every part meets the tightest tolerances and highest performance expectations.

Ready to partner with a manufacturer that understands the demands of the aerospace industry? Contact our team today to learn how we can deliver precision CNC parts tailored to your needs.