Engineers in every industry know the importance of metal parts that meet strict precision and performance requirements. Particularly in industries like aerospace and transportation, you need metal components that meet your standards for quality, adhere to safety standards, and deliver in functionality. That’s where CNC machined parts come in. CNC machining is one of the most widely used manufacturing processes in the world thanks to its speed and its high levels of precision and consistency. When it comes to choosing CNC machined parts for your critical applications, here is what you need to know.

How Does CNC Machining Produce Complex Parts?

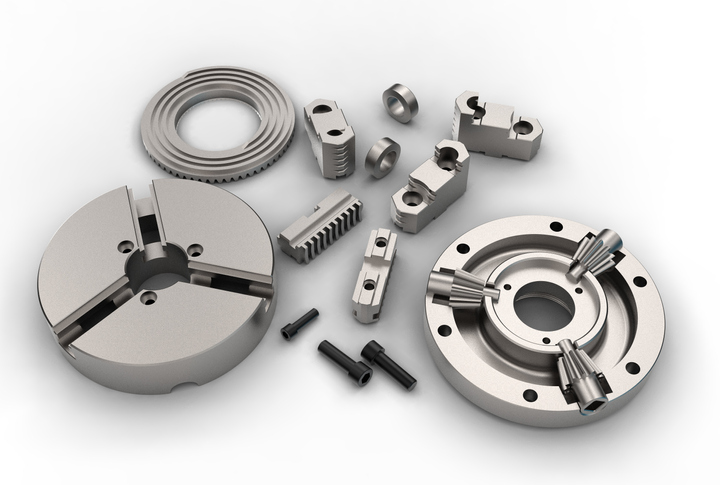

CNC (Computer Numerical Control) machines use computerized controls to move and operate the cutting tools along a series of axes. The most commonly used CNC machines are 3-axis and 5-axis machines, but the number of axes can go up to 12 in the more advanced systems.

And it’s these axes that allow for the production of complex metal components. Take a 3-axis machine, for instance. In a 3-axis CNC machine, the areas of operation include the X-axis (horizontal movement along the length of the piece), the Y-axis (horizontal movement along the width of the piece), and the Z-axis (vertical movement controlling the depth of the cutting tool).

The machine is capable of moving the cutting tool along all of these axes, allowing for the fast and efficient production of extremely complex parts with intricate geometries. And with capabilities like tool and pellet changes, CNC machining can incorporate multiple operations into a single setup, enabling a faster and more cost-effective process that can produce identical complex parts repeatedly.

Design and Tolerance Considerations for CNC Machined Parts

For engineers, there are a number of things to keep in mind when designing and defining tolerances for CNC machined parts. Outside of part functionality and durability, it’s important to design your part for the manufacturing process. You’ll want to consider factors like:

- Cost — A number of factors can impact the total cost of your CNC machined parts, including setup, programming, material selection, part complexity, and production volume. Taking all of this into account during design will help ensure that your part has been optimized for the most cost-effective solutions.

- Lead Time — Lead times in CNC machining can be influenced by everything from tolerance requirements and part complexity to machine setups and standard vs custom tools. A well-designed part can help reduce lead times and enhance productivity.

- Design Feasibility — Finally, be sure to consider whether or not your part is well-suited for the CNC machining process. For instance, if you need cavities that are less than 2.5 mm in diameter, this is typically considered micro-machining and may require specialized tooling to achieve.

In regard to tolerances, the material, tooling, and part complexity can all have an effect. Keep in mind that while CNC machining is capable of producing parts with extremely tight tolerances, the cost of production will likely be higher than if you were prototyping with looser tolerances.

When is it Best to Opt for CNC Machined Parts?

So, when do CNC machined parts make the most sense? In general, if your part needs to meet these three criteria, then CNC machining is likely the best manufacturing solution for you.

- Small to medium volume requirements — CNC machining is best suited for low to medium-volume productions due to a variety of elements including setup costs, tooling costs, and cycle time.

- Complex parts with intricate geometries — Because of its sophisticated capabilities, CNC machining is an excellent choice for complex parts that require intricate geometries.

- Shorter lead times are a priority — Due to the inclusion of multiple operations in a single setup, the process for manufacturing complex CNC machined parts can be much faster and more efficient than other manufacturing solutions.

When To Consider Other Options

While CNC machining is a versatile and highly precise process, it may not always be the most efficient or cost-effective process in some cases. For instance, if you need a high volume of parts, then a high-volume process like metal stamping might be a better option.

Similarly, if budget is a major concern, you may want to opt for a process that has a lower initial investment, such as stamping or sheet metal fabrication.

And finally, keep in mind that while most materials are suited for CNC machining, there are a few that don’t perform well due to the high level of heat involved in the process.

Experience Performance with CNC Machined Parts From OGS Industries

For more than 60 years, OGS Industries has been producing high-performance CNC machined parts for a wide range of industries. We got our start in gaskets and shims, but today, we are a full-service machine shop that offers engineering assistance, prototyping, machining, stamping, fabrication, assembly, and inventory stocking programs so you can get everything you need in one place.

Our portfolio of customers includes Fortune 1000 names like GE, Honda, Volvo, and Lockheed Martin. But we’re proud to provide manufacturing solutions for a diverse selection of companies in Ohio and the surrounding states.

Are you looking for high performance metal parts? Connect with our team today to get started with a free quote.