Precision metal parts play a fundamental role in modern manufacturing, maintenance and repair, and equipment across automotive, firearm, aerospace and defense, transportation, power sports, and medical applications — and require careful attention to maximize quality and production. With an experienced team, precision manufacturing can provide greater accuracy, increased repeatability, and efficiency, all with reduced material waste and time savings. With modern machining innovations, companies are now empowered to quickly design new parts, or modify existing ones, without having to invest heavily in specialized machinery.

Whether your focus is on composition or performance, success begins with designing your part and meeting the required specifications. The most important characteristic of your precision metal components will vary depending on your application and your production goals.

When considering your next machining partner, be sure to identify a partner experienced in quality management practices, improved traceability, and better lead times. If you are experiencing inconsistency and supply issues with your current supplier, learn how we can help you get back up to speed.

Fitting Your Metal Components for Optimal Performance

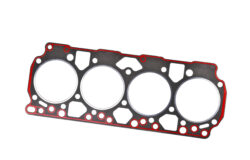

From threads to holes, grooves, or tapers, parts for aerospace, firearms, medical instruments, and engine parts require intricate features and precise specifications. If your parts don’t have an exact fit with other components, they are unlikely to function properly and could result in defects and costly consequences.

When parts are formed to exact specifications using CNC machines, accuracy and reliability increase substantially compared to methods like manual fabrication. Besides having the right technology, the precision process requires expert machinists skilled in meeting specifications and delivering tight tolerances. By choosing your materials wisely, ensuring tools are in good shape, reviewing your parts design, and appropriately adjusting tolerances, you will be in a good position to create metal components fit for purpose.

Master The Machining Process for Greater Reliability

As mentioned, precision machining processes allow for greater accuracy and reliability. Thousandths of an inch can make all the difference for manufacturers. With an experienced team and modern computer software, you can benefit from precise cuts within limited margins of error. Common processes and machines for precision machined components across the highest-growing industries include:

Precision CNC Machining — Known to be the best way to control and monitor the precision process. Not only are parts and components accurate but they are consistent and repeatable.

Swiss Screw — Swiss screw machines have the unique ability to deliver small, high-precision parts and are perfect for close tolerance and complex parts under 1.5 inches in diameter.

Lathes — Easily increase the efficiency of mass production and make intricate, smooth solid objects from just a single piece of material under 3 inches in diameter. Accurate and cost-efficient, lathes easily shape and form various metals into your desired shape and size.

Milling — CNC milling has the ability to hold very tight geometric tolerances for many aspects of a part’s key features. Components produced on CNC milling machines are typically square or rectangular with numerous features.

Quality Products Guaranteed with Quality Control

Metal components play a crucial role in creating high-quality products — and meeting end consumer expectations. Partnering with a trusted team committed to quality control at every step of the process remains an essential way to protect your brand and ensure your product’s functionality and safety. Consistency and regular testing are two common ways manufacturers like OGS ensure both quality control and safety.

While considering the technical aspects continue to remain important — from tolerance, tools, features, part compatibility, and functionality, other elements like process controls, record keeping, quality material tracking, inspections, and certifications also play a critical role in preventing reliability issues. At OGS, our AS9100-certified machining facilities specialize in low-to-medium-volume metal part manufacturing. In industries like aerospace, with high quality demands, our team delivers with regulations in place to ensure the safety and reliability of materials and equipment.

Get Ultimate Results with an Experienced Team

The cost of machinery, labor, specialized insight and tight tolerances can be high. When products are produced with a proven manufacturer, however, they can be produced quickly and accurately, with less waste. This way, companies find savings down the line by experiencing fewer defects and increasing their throughput. Getting ultimate results comes from having the right tooling and machinery, industry expertise, years of experience, using modern software and technology, and having specialized operators.

It is important to remember that with modern manufacturing, precision doesn’t need to detract from productivity. You can continue to produce thousands of the same metal components with consistent specifications, tolerances, and quality. At OGS, we prioritize cost, quality, and speed to deliver on-time high-quality components at the lowest cost. We take pride in our core competencies and state-of-the-art facilities, equipped with the latest technology.

Have questions about creating precision metal components? Our team is happy to review your design help you improve your production process today.