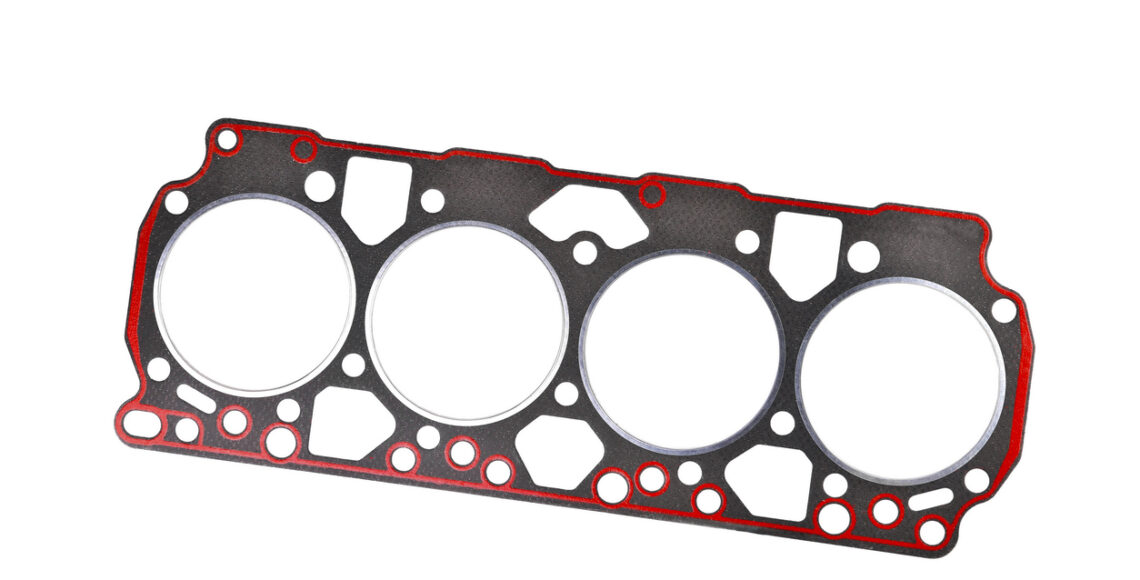

Metal gaskets are critical components that are often the last line of defense against leaks and pressure loss in demanding environments. Industries like the automotive and aerospace industries, in particular, rely heavily on crush gaskets to maintain system operations and integrity.

However, not all gaskets are created equal. The quality of the material, the precision of the manufacturing process, and the ability to customize and scale production are all factors that can make or break the performance of your gaskets.

At OGS, we specialize in producing metal crush gaskets that meet the most stringent industry standards, ensuring that your systems remain secure and efficient under the toughest conditions. To get a better understanding of how we pull this off, read on.

Material Expertise for Metal Gaskets and Crush Gaskets

Material selection is one of the most critical factors in the performance of crush gaskets. The right material ensures that gaskets can withstand extreme temperatures, pressure variations, and corrosive environments without compromising their sealing capabilities. For instance, stainless steel is a common choice for applications that require corrosion resistance and durability. And aluminum and copper are preferred for their malleability and thermal conductivity.

At OGS, our material expertise is rooted in decades of experience and a deep understanding of how different metals behave under stress, as well as during the manufacturing process. We offer a wide range of material options, including stainless steel, copper, aluminum, and high-performance alloys, ensuring that your crush gaskets are built to last and perform reliably in their intended environment.

Our team also works closely with you to select the most suitable material based on your application’s unique demands, providing you with a gasket that maintains its integrity over time.

Precision Manufacturing Capabilities

When it comes to crush gaskets, even the slightest deviation from the specified dimensions can lead to leaks or failure to maintain pressure. High-precision manufacturing techniques like CNC machining and advanced metal stamping are essential to achieving the exact dimensions and tight tolerances required for these critical components.

Precision ensures that each gasket fits perfectly within its assembly, creating a reliable seal that prevents leaks and maintains pressure in various applications, from automotive engines to aerospace systems.

At OGS, we’re equipped with cutting-edge machinery and skilled technicians who specialize in precision manufacturing. Our capabilities include CNC machining, metal stamping, and fabrication, all designed to produce gaskets with the highest degree of accuracy.

We understand that in industries where safety and performance are paramount, precision is not just an advantage—it’s a necessity. By choosing OGS, you’re ensuring that your gaskets will consistently meet the stringent standards required for your applications.

Customization Options

Every application has unique requirements, and standard gaskets may not always meet those needs. Customization is key to ensuring that gaskets fit perfectly within their intended assemblies and perform their sealing functions effectively. This can mean designing gaskets with specific shapes, sizes, and thicknesses, or using a combination of materials to achieve the desired properties. Considerations such as the type of fluid being sealed, the operating pressure and temperature, and the mechanical stress the gasket will endure all play a role in the customization process.

Our team at OGS offers extensive customization options to address the diverse needs of our clients. Whether you need gaskets with complex geometries, unique material combinations, or specific surface treatments, we have the expertise to deliver tailored solutions.

We collaborate with you from the design phase through production, ensuring that every detail is considered and that the final product meets your exact specifications. With OGS, you can be confident that your custom gaskets will enhance the overall performance of your systems.

Scalability for Metal Gaskets and Crush Gaskets Production

Scalability is a crucial factor for businesses that require consistent quality and timely delivery of gaskets, whether they need a small batch for prototyping or large volumes for mass production. The ability to scale production efficiently allows manufacturers to respond quickly to market demands. This scalability also supports the cost-effective production of gaskets, ensuring that they remain affordable while maintaining high quality.

At OGS, our scalable manufacturing solutions can adapt to your production needs. Whether you’re in the early stages of product development or ramping up for full-scale production, we have the capacity to adjust our processes to match your requirements. Our production facilities are designed to handle everything from short runs to high-volume orders without sacrificing quality or precision. Partnering with OGS means you can rely on a consistent supply of high-quality gaskets, no matter the size of your order.

Ensure the Performance of Your Gaskets with OGS

The performance of your metal gaskets is critical to the overall success of your products. At OGS, we understand that even the smallest component can make a significant difference in the reliability and safety of your systems. Our comprehensive approach to gasket production—encompassing material expertise, precision manufacturing, customization, and scalability—ensures that your gaskets will perform flawlessly under the most demanding conditions.

Our capabilities include metal stamping, fabrication, and CNC and Swiss machining. We also offer a variety of assembly services, value-added services, and logistics support for one-stop solutions that meet your every need.

Trust OGS to deliver the high-quality, high-performance gaskets you need to maintain pressure, prevent leaks, and ensure the integrity of your systems. Get in touch today to get started.