The High Cost of Cheap Parts

As a business owner or project manager, it’s understandable to want to save money wherever possible. However, when it comes to choosing a metal fabrication partner for your projects, low-quality metal fabricators can end up costing you much more in the long run. When searching for the right metal fabricating partner, capabilities and experience should be major factors in the final decision.

However, many companies look at cost first despite the fact that choosing the lowest-cost metal fabricator could cause serious problems.

Low-Quality Metal Fabricators Produce Poor Quality Parts

In the metal fabrication industry, lower costs are usually a red flag that the manufacturer is cutting corners somewhere. Whether that means using cheaper materials that will not hold up long-term or spending less time in essential process steps such as quality assurance, the result is usually poor quality parts that do not meet the standards or needs of your application.

Poor quality parts can lead to end-product defects and safety hazards for end users. Common signs of parts produced by low-quality metal fabricators include:

- A Failed Visual Inspection – If the metal part has visible surface issues like rust, dents, scratches, or laminations, these are all signs of low-quality production and can point to deeper issues with part strength and durability.

- Failure to Meet Tolerance Specifications – Adhering to tight tolerances is essential in precision metal parts. If a metal fabricator has trouble consistently and accurately delivering parts that meet the parameters you provided them, this indicates improper tooling, low-quality production parameter control, and a lack of proper quality assurance measures.

Lower Costs Sometimes Mean Increased Production Times

Low-quality parts that are not built to your specifications can necessitate the grueling process of sending large quantities back to the manufacturer for corrections. Not only can this significantly delay your project timelines, which leads to higher costs and loss of revenue, but it’s unlikely that the issue will be resolved on your next production run.

In a worst-case scenario, the cause of the low-quality parts could be a combination of a variety of factors, including improper tooling, improper material selection and handling, and poorly engineered dies to name only a few. Taking the time to identify and fix all of these issues can add weeks or even months to your production time and cause you to miss important deadlines.

Could Lead to Higher Costs in the Long Run

If you’re sourcing metal parts for use in your own products or equipment, low-quality parts could contribute to an increased need for maintenance and replacement. At best, this could mean higher labor costs for the maintenance services required. At worst, the metal parts could give out during a critical period in your operations and bring everything to a grinding halt.

While some repairs and maintenance are unavoidable, sourcing metal parts from a low-quality metal fabricator will ensure that you invest much more into these areas than you need to.

Low-Quality Metal Fabricators Damage Your Reputation

Delivering a product that doesn’t meet the expectations of your customers or the standards of your industry is one of the fastest ways to lose trust and damage your reputation. When it comes to end-products, their quality is only as good as the quality of the parts you use.

Partnering with a low-quality metal fabricator who is more concerned with cutting costs to gain your business than with helping you maintain your integrity is a sure way to lose customers and revenue.

The Benefits of Working with a High-Quality Metal Fabricator

Partnering with high-quality metal fabricators helps you avoid issues like poor-quality parts, longer production times, and higher costs in the long run. While initial costs may be higher, it’s important to consider the long-term benefits and savings that come with choosing a more skilled fabrication partner.

Quality metal fabricators use only the best in high-grade materials and employ skilled professionals to ensure that your product is built to last. By utilizing the necessary and correct tools and equipment, and implementing rigorous quality control standards to ensure that every piece meets your needs, high-quality metal fabricators can be an invaluable part of your business.

Above all, partnering with a high-quality metal fabrication company means putting your business in the hands of someone you trust to meet your needs and uphold your company values and standards.

Get Only the Best With a Seasoned Quality Metal Fabricator

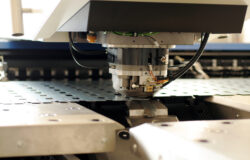

At OGS, we balance cost with quality and efficiency to bring you the best in metal fabricating services. With 60 years of experience, we pride ourselves on our high-quality one-stop-shop metal manufacturing capabilities, including stamping, fabrication, CNC machining, welding, and assembly.

We place the highest priority on delivering quality metal products and answering your questions and concerns with top-notch customer service.

Ready to get started with a quality metal fabricator you can trust? Get in touch with our team today.